Solar cell

A solar cell or photovoltaic cell is a device that converts solar energy into electricty by the photovoltaic effect. Solar cells have many applications: individual cells are used for powering small devices such as electronic calculators; photovoltaic arrays generate a form of renewable electricity, particularly useful in situations where electrical power from the grid is unavailable such as in remote area power systems, Earth-orbiting satellites and space probes.

A traditional solid-state solar cell is made from two doped crystals (P-N junction), like silicon solar cell.

Fig.1 A solar cell made from a monocrystalline silicon wafer

![]() Fig.2 Polycrystaline PV cells laminated to backing material in a PV module

Fig.2 Polycrystaline PV cells laminated to backing material in a PV module

Dye-sensitized solar cells (DSSC)

Dye-sensitized solar cells (DSSC) based on a semiconductor formed between a photo-sensitized anode and an electrolyte, a photoelectrochemical system. These cells were invented by Michael Grätzel and Brian O'Regan and are also known as Grätzel cells

Dye-sensitized solar cell (DSSC) provides us a technically and economically viable alternative way for traditional p-n junction silicon solar cells. Although they use a number of "advanced" materials (like TiO2 nanoparticles) , these are inexpensive compared to the silicon needed for normal cells because they require no expensive manufacturing steps. TiO2, for instance, is already widely used as a paint bas. The record of liquid-electrolyte based DSSC can reach a conversion efficiency of 11%.

Simple comparison of P-N junction solar cell and DSSC

In P-N junction solar cell semiconductor achieves task of light absorption and charge carrier separation and transportation. While in DSSC these functions are separated. the bulk of the semiconductor is used solely for charge transport, the photoelectrons are provided from a separate photosensitive dye. Charge separation occurs at the surfaces between the dye, semiconductor and electrolyte (or organic hole transport materials). By combining a sensitizer as a light- absorbing material (a broad absorption band) with a wide-bandgap semiconductor films of mesoporous or nanocrystalline morphology permits harvesting a large fraction of sunlight.

Fig.3 DSSC Demonstration

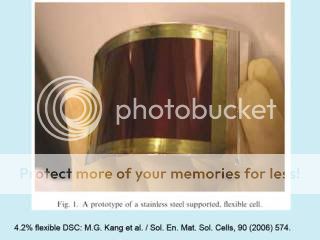

Fig.4 A prototype of a stainless steel supported flexible DSSC.

DSSC Structure

The basic structure of the Dye-sensitized solar cell is that in the case of the original Grätzel design: the cell has three primary parts. Glass sheet with transparent conducting oxide coating (ITO or FTO) as anode on top of it; and semiconductor oxide (normally mesoscopic TiO2which forms into a highly porous structure with an extremely high surface area. ) film deposits on the conductive side of the glass sheet which is then immersed in a mixture of a photosensitive ruthenium-polypyridine dye (also called molecular sensitizers[5]) and a solvent. After soaking the film in the dye solution, a thin layer of the dye is left covalently bonded to the surface of the TiO2. A separate backing is made with a thin layer of the iodide electrolyte spread over a conductive sheet, typically platinum metal.The front and back parts are then joined and sealed together to prevent the electrolyte from leaking.

Fig.5 Schematic of the construction of Grätzel cell.

Basic working principle

We elaborate the the mechanism of DSSC using Dye-sensitized solid-state heterojunction solar cell as an example which we will focus on.

In Dye-sensitized solid-state heterojunction solar cell, a monolayer of dye is attached to the surface of a mesoscopic film of TiO2 (wide-bandgap oxide) and serves to harvest solar light dye absorbs light and then injects electrons into the conduction band of semiconductor oxide (the nearby TiO2 particles) upon excitation, then the electrons transport through its nanoparticle network by diffusion to the current collector (anode),subsequently pass through the external circuit, perform electrical work, processed to the counter electrode (cathode)at the mean while, the dye also injects holes to the hole conductors and transport to the counter electrode, and with the outside circuit which the finishes loop. And there is no chemical change under solar exposure. The Only difference for original Grätze cell compared with Dye-sensitized solid-state heterojunction solar cell is that the former uses electrolyte and the latter uses as hole conducting medium.

Fig.6 Schematic illustraion of the working principle of original Grätze cell

Fig.7 Schematic illustraion of the working principle of Dye-sensitized solid-state heterojunction solar cell

Inorganic electron conductor

The semiconductor oxide materials (with wide-band gap) TiO2 (anatase) serves to harvest the solar light, which only absorbs a small fraction of the solar photons (those in the UV).[5] However when we combine the this wide-band gap semiconductor of mesoporous or nanocrystalline morphology with the sensitizers(Dye) of broad absorption band, this interpenetrating network junction can harvest a large fraction of the sunlight. There are other alternative semiconductor oxides such as ZnO, SnO2, Nb2O5 which are not as good as TiO2 under current investigations.

In DSSC, the inorganic films are made of a network of wide-band-gap oxide

nanocrystallites, producing a junction with large contact area. The surface amplification for a film composed of 15~20 nm sized particles is about 100 times the area it occupied for each micron of thickness. A roughness factor, real surface/projected area,

of at least 1000 to ensure efficient light harvesting.

Fig.8 a) scanning electron micrograph of TiO2 film. b) orientation of exposed facets of the particles. and c) histogram showing the frequency of occurrence of a given particle size for a mesoscopic TiO2 film prepared at 230oC, which has demonstrated optimal photovoltaic performance so far

The film thickness is 5~20um, the TiO2 mass—1-4mg/cm2, the Porosity is 50~65% and the average particle diameter is 20nm. The prevailing structure of anatase– bipyramidal , pseudocubic, bricklike. The Most expose face (101) then (100) and (001). The formation of the (101) is favored by its low surface energy. The oxide particle are in the intrinsic insulating state (without doping). However, the injection of one single electron from the dye into the TiO2 particle which then switched from an insulating to a conducting state.

The TiO2 film is deposited by screen printing from a colloidal suspension providing a reproducible and controlled porous high-surface area texture. Presently, hydrothermal route is used since it is ease to control particle size hence of the nanostructure and porosity.

Organic hole transport Materials

Spiro-MeOTAD in this work.

• The spiro center confers to the material in a high

thermal stability in the glassy state without adversely affecting its electronic properties

• 120 °C of the glass-transistion temperature

assures stability of the amorphous state under

ambient conditions for years.

• Crystallization is undesiable, as it prevents the

close contact between the hole transport

materials with the oxide film.

Sensitizing dye itself does not provide a

conducting functionality, but it distributed at an

interface in the form of immobilized molecular

species.

•1x10-4 cm2/V s hole mobility.

Now a days people are growing TiO2 nano-wire which effectively separates electron and hole can you discuss it more.

Could you offer some information about the strucure of TiO2 . Is it nanocrystalline TiO2? How about the phase, anatase, rutile? And the requirements for the TiO2 used.

Hey guys, I have updated the TiO2 structure. Hope that would be useful for you.

And actually people have tried TiO2 nano-wire for DSSC, although there are improved electron and hole separation rate, the surface to volume ratio is not high enough compared with the nanoparticle, hence not much improve in the efficiency.

References

1. B. O’ Regan and M Gratzel, “A low-cost, high-efficiency solar cell based on dye-sensitized colloidal TiO2 films”, Nature 353 (1991)p737

2. M. Gratzel, ‘Photoelectrochemical cells”, nature 414(201) p. 338

3. Law, M. ; Greene, L.; Johnson, J.; Saykally, R.; Yang, and P. Nanowire dye- sensitized solar cells. Nature Mater. 4, 455 (2005)

4 M.G. Kang et al. Sol. En .Mat. Sol. Cells, 90 (2006) 574

5. O’Regan B., Grätzel M Electrical circuit of a DSC,., Nature 353 1991

6 http://en.wikipedia.org/wiki/Dye-sensitized_solar_cell